Versione HTML di base

5

PRESS REVIEW

Blueing and nickel finish

components in-house, even casting moulds

and machining tools are designed and

built by Chiappa to guarantee maximum

reliability and production continuity.

All steel parts are turned from steel

bars or milled from solid steel blocks.

“High precision turning machines

can produce very small metal parts,

machining steel bars with the tightest of

tolerances. The CNC milling machines

can mount many different machining tools

to carry out countless contemporaneous

machining operations.

The final result of machining

precision, final bolstering with porcelain

pebbles and hand polishing of all parts

yield perfectly smooth and fluid actions

in our products.

Costa Giampietro, a Chiappa Group

company that specializes in the surface

treatment of metal parts, does all of the

Chiappa Products blueing, nickel-plating,

and polishing in Italy, thus guaranteeing

a perfectly smooth and eye-pleasing finish

time and time again.

The fitting of wood and metal parts

is performed manually in two separate

steps. Raw wood and metal parts are

assembled and polished together.

After which the parts are again

disassembled and numbered. Barrels and

receivers are sent to the Proof House with

rough stocks (which are often damaged

during the tests), wooden parts are

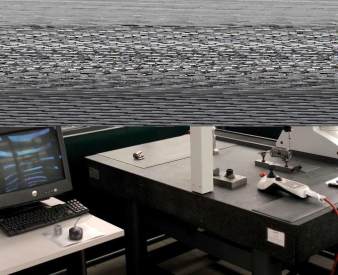

NC machining of pistol breech block

Various stage of assembly of handguns

coloured and hand oiled, while metal parts

are polished and tempered.

Finally all parts are re-assembled,

insuring that the wood to metal fit is

perfect. Fitting this way is an expensive

operation, in terms of time and cost.

“The pleasure of looking at, and handling

a firearm with perfect wood to metal fit,

is however incomparable” assures Mr

Chiappa.

All stocks and forends are manually

oiled 3 to 4 times. Though manually oiling

is a lot more expensive than varnishing,

hand oiling respects traditions and has a

distinct advantage. In case an oiled stock is

scratched, it can be restored by sanding and

Office personnel

re-oiling the scratched area. A varnished

stock meanwhile is not repairable.

Constantly investing in leading

edge machinery, logistics organization,

employment of specialized and professional

workers Chiappa says can guarantee a

reliable, qualitative, and cost competitive