Versione HTML di base

88

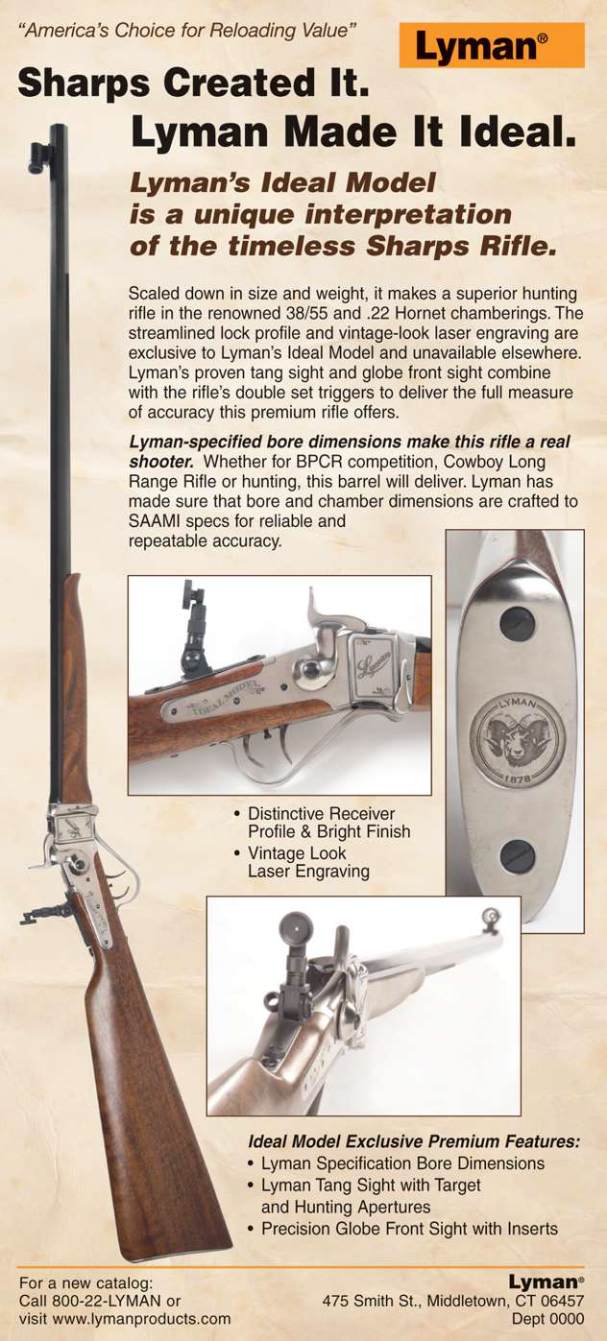

SHARPS

made sporting versions from

the late 1840s until the late 1880s. After

the

AMERICAN CIVIL WAR,

conver-

ted Army surplus rifles were made into

custom firearms, and the Sharps factory

produced Models 1869 and 1874 in large

numbers for the

COMMERCIAL

BUFFALO HUNTERS AND

FRONTIERSMEN .

“

”

55 Lyman reloading die set. During

the necking process, I crushed four of

the Winchester cases, and five of the

Remington cases.

Four percent failures rate for the

annealed cases versus 25 percent for non-

annealed shows an obvious benefit.

Even though the converted .30-30

cases were shorter than specified, they

worked fine for the rifle’s break-in and

plinking loads.

I had trouble locating new .38-55

brass, but was able to find some once-

fired .375 Win to use in testing. The two

different .38- 55 case lengths exist, 2.125-

inch and 2.080- inch. Starline Brass makes

both lengths. Winchester is another source

for .38-55 brass. In a pinch, .375Win brass

can be used as well.

Two days before finishing this

article, I did receive some new .38-55Win

brass and put it to use.

For starting loads, I used Reloader

7, IMR 4198 and Accurate 5744. Without

much loading data available, I decided to

start low with powder charges and work up

to loads that performed well enough to get

a feel for the rifle and optics.

I measured powder charges with

an old RCBS 5-10-5 scale and used a

handloading tool to seat five bullets for

velocity testing.

When I got the speed up to

minimum velocities, I loaded enough

shoot groups. My first load of IMR 4198

was 16 grains, which produced an average

of 1,175 feet per second (fps) with the

RCBS 312-grain cast bullet. Bumping the

charge to 18 grains produced an average of

1,296 fps, which was fast enough to start

punching paper.

I learned quickly that the 1-in-18-

inch twist rate for this rifle wasn’t fast

enough to stabilize the long 312-grain

RCBS bullet. Every shot was keyholed -

even though it printed a 5-inch, three-shot

group at 100 yards.

To confirm that the heavier bullets

were not compatible with the slower twist

rate, I loaded 18 grains of 4198 behind the

Lyman 330- grain bullet and proceeded to

put elongated holes in targets.

Crossing these bullets off my list,

I started working the other two bullets.

The 249-grain Lyman 375248 bullet

and the Lyman 375449 gas-checked bullet

were cast from a 50:50 alloy of linotype

and clipon wheel weights.

This alloy has a Brinel hardness of

17, which is higher than I would want

for hunting loads, but is fine for target

shooting.

The 249-grain Lyman 375248

averaged 1,435 fps when pushed by 20

grains of IMR 4198, and produced 2.13-

inch 5-shot groups at 50 yards with factory

sights.

At 100 yards with the Malcolm 3x

scope groups measured 2.58 inches.

I tried 23 grains of Accurate 5744

behind the 264-grain Lyman, and got a

1,638 fps average.

At 50 yards with iron sights, this

load kept five shots under two inches,

and at 100 yards with the 3x scope its best

group measured 1.28 inches.

Late in the testing, I was able to

purchase a box of Winchester 250-grain

factory ammunition to form a basis of

comparison with the cast bullet loads.